“You wouldn’t say, let me go buy an enterprise car,” Apple Chief Executive Officer Tim Cook told Box CEO Aaron Levie at the BoxWorks conference in San Francisco this week . “You don’t get an enterprise pen to write with.”

Cook was talking about Apple’s position in the enterprise computing world, something conventional IT industry wisdom says isn’t the company’s strong point.

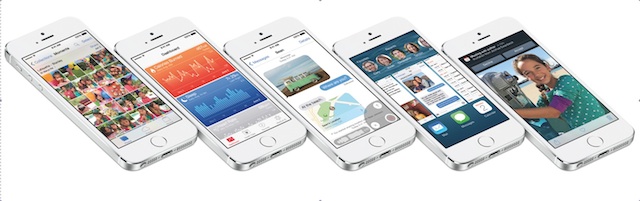

While this was true in the days of desktop computers and network servers, the arrival of the iPhone and iPad changed that. Suddenly Apple were driving business computing as staff from the Chairman of the Board down to the office junior started bringing in iOS devices.

Up until the iPad, the Bring Your Own Device discussion was a debate, once the tablet appeared any argument was over as all levels of businesses started bring their devices into the office.

One of the key arguments for using an iPad were the applications available and one of the most important applications in the early days was Evernote.

Sadly for Evernote, those early successes haven’t continued and now the company is being flagged as potentially the first billion dollar ‘tech unicorn’ to fail.

If Evernote does fail, it will show that even having a compelling product at the right time isn’t a guarantee for success.

Apple however is basking in its success and, as Cook points out, the shift to mobile is now defining business and his company is probably the best positioned to exploit that.

Similar posts: