The second day of Autodesk University 2015 in Las Vegas continued the focus on innovation and changing industries, the afternoon innovation session was particularly focused on some of the opportunities being realised in drones, pre-fabricated buildings and lampshades made out of fungus.

Brooklyn based designer Danielle Trofe gave a great demonstration of how she’s using fungus to create a range of sustainable light shades. Interestingly in a conversation earlier in the day with Autodesk CTO Jeff Kowalski the topic of growing products out of Mycelium, the vegetative part of a fungus that Trofe uses, was discussed in terms of smart packaging and biodegradable products.

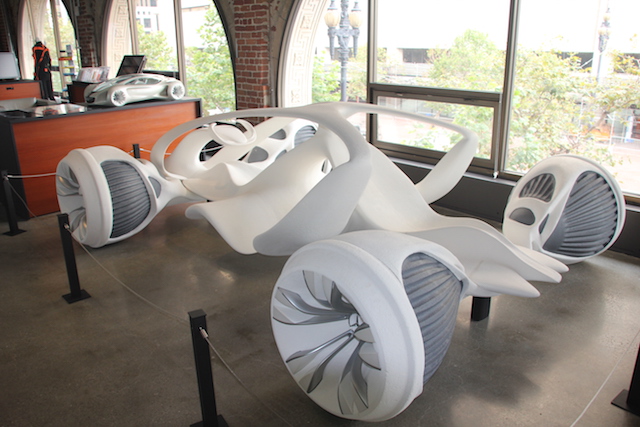

Growing products out of organic material is one of the themes explored in Mercedes Benz’s Biome concept car which proposes to grow the chassis out of seeds. While realising that concept is some way off, Trofe’s Mush-Lume idea shows some products are already at that stage.

Rethinking prefab buildings

Following Trofe was Jos Mulkens, the CEO of Dutch building company Voorbij Prefab, who described how by using sophisticated design tools and 3D printing to make prefabricated building panels they had reduced to the time to fabricate elements from days to hours.

Mulkens gave a good insight into how design and production workflows are being accelerated with modern technology, particularly in replacing manual form makers to make the moulds for the precast panels. Voobij Prefab are flagging a lot of disruption heading for the building industry.

At one the media breakout sessions a group of senior Autodesk managers discussed the trends in design and materials engineering. This turned out to be an interesting session on the limits of current technologies.

Composite technologies

Max Moruzzi, Autodesk’s Principal Research Scientist, is a passionate believer in composite materials and the benefits they promise. However he conceded when challenged by his colleague Steve Hobbs, who joined Autodesk last year with the acquisition of UK based Computer Aided Manufacturing company Delcam, about the structural properties of composites that we still have a lot to understand about how they behave and fail.

Bringing a touch of English scepticism to the panel, Hobbs pointed out almost all metallic components made by 3D printing require some sort of mechanical, subtractive finishing such as milling or polishing.

Hobbs went onto warn that we risk introducing a “hairball of complexity” into the design and manufacturing industries as people experiment with developing products with materials and techniques they don’t fully understand.

All the panel, which also included Carl White – Autodesk’s senior director of marketing for advanced manufacturing – and Benjamin Schrauwen who leads the company’s Spark 3D printing division, agreed that applying current design and manufacturing methods need to be rethought in the light of new methods being developed.

The limits of 3D printing

It was notable in the panel Q&A around the revelation that 70% of 3D printing projects fail, the panel put this down to the relative immaturity of software and machinery along with the technologies currently being poorly understood. Hobbs observed that for GE to 3D print their jet engine parts they rebuild and reprogram the printers they buy to their own higher specifications.

For the final session CEO Carl Bass and CTO Jeff Kowalski faced a Q&A from analysts and the media, that session was interesting in exploring some of the directions Autodesk sees industry and business heading and I’ll write more about that tomorrow.

Overall, the Autodesk University has been an interesting insight into the future of design and manufacturing along with the effects this has on other industries. With these technologies at an early stage, it’s a field that is going to evolve rapidly.

Paul Wallbank travelled to Autodesk University in Las Vegas as a guest of Autodesk.